Emerging Trends in Prosthetic Materials: What Medical Professionals Should Know

In recent years, custom prosthetics have seen incredible advancements, driven by innovative materials, cutting-edge prosthetic technology, and a deeper focus on patient outcomes. For medical professionals, staying updated on the latest trends in prosthetic materials is essential to provide patients with solutions that are not only functional but also enhance their quality of life. This article dives into some of the most significant emerging trends in prosthetic materials, offering insights into how these advancements are reshaping the future of prosthetics.

1. Lightweight Composite Materials

One of the primary challenges in custom prosthetics has always been achieving the perfect balance between strength and weight. Patients often seek lighter devices that do not compromise durability or functionality. Lightweight composite materials, such as carbon fiber and advanced polymers, have become highly sought-after options due to their unique strength-to-weight ratio. These materials allow for the development of prosthetics that feel more natural to wear, reducing strain and enhancing long-term comfort for patients.

Carbon fiber, for example, is not only incredibly durable but also extremely lightweight, which helps patients with mobility. For medical professionals, understanding these materials’ benefits can lead to better-informed recommendations, ultimately boosting patient satisfaction and improved outcomes.

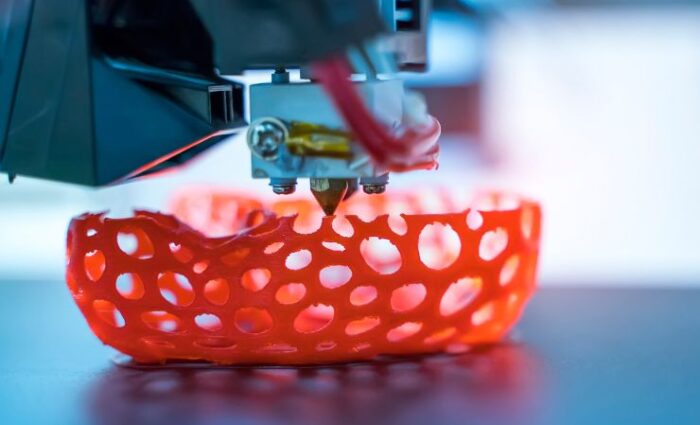

2. 3D Printing in Prosthetic Fabrication

3D printing has revolutionized many aspects of the medical field, and prosthetics is no exception. This technology allows for precise customization, enabling the creation of bespoke prosthetics that fit each patient’s unique anatomy with minimal adjustments. The accessibility of 3D printing has also reduced production costs and wait times, making it easier for more patients to access custom prosthetics tailored to their needs.

The materials used in 3D printing are advancing rapidly as well, with innovations in both biocompatible plastics and flexible filaments. These materials help create prosthetics that offer a more natural range of motion, contributing to better patient outcomes. With 3D printing, medical professionals can offer a tailored approach that meets the specific functional and aesthetic needs of each patient, increasing comfort and enhancing the overall rehabilitation process.

3. Silicone and Thermoplastic Elastomers for Enhanced Comfort

Another significant development in prosthetic materials is the use of silicone and thermoplastic elastomers, which have quickly become popular for their flexibility and comfort. These materials provide a soft interface between the prosthetic device and the skin, reducing irritation and improving the prosthetic’s adherence to the residual limb.

Silicone liners, in particular, have proven effective in managing friction and pressure, making them an excellent choice for patients with sensitive skin or those prone to skin issues. Thermoplastic elastomers offer similar benefits, providing a lightweight, flexible option that still offers durability. Medical professionals should consider these materials when working with patients who prioritize comfort and skin health, especially those requiring extended wear times.

4. Smart Prosthetic Materials and Embedded Sensors

Smart prosthetics represent one of the most exciting advancements in the field, combining custom prosthetics with sensor technology that enhances their functionality. Embedded sensors can detect and respond to various external stimuli, allowing the prosthetic to adjust based on the patient’s movements. These smart prosthetics often use materials that conduct signals, enabling real-time communication between the prosthetic device and the user’s body.

For instance, sensors embedded in the foot of a prosthetic leg can adjust the resistance based on the terrain, providing greater stability on different surfaces. By understanding the possibilities of these smart prosthetic technologies, medical professionals can help patients achieve a higher level of independence and control over their movements, which positively impacts patient outcomes.

5. Biodegradable and Sustainable Materials

As healthcare moves toward more sustainable practices, the use of eco-friendly and biodegradable materials in prosthetic design is becoming more prevalent. These materials are not only environmentally friendly but also help to reduce medical waste, which has long been a concern in the healthcare sector. Materials like PLA (polylactic acid), derived from renewable resources, are being explored for certain prosthetic applications.

For medical professionals interested in sustainable options, these materials may offer an opportunity to support patients who are conscious about their environmental footprint. Additionally, the development of biodegradable materials could mean that in the future, discarded prosthetics may break down without harming the environment, aligning with global sustainability efforts.

6. Antimicrobial Materials to Reduce Infection Risk

One of the emerging trends in prosthetic materials is the use of antimicrobial components, which help to reduce the risk of infection. These materials are particularly beneficial for patients who live in warm or humid climates, where bacteria and fungi are more likely to thrive. By using antimicrobial materials, manufacturers aim to create prosthetics that are safer and healthier for the patient to wear, especially over extended periods.

For medical professionals, suggesting prosthetics with antimicrobial properties can significantly improve patient outcomes by minimizing the risk of complications. This trend highlights the importance of both functionality and safety in prosthetic design, underscoring the need for materials that align with patient health concerns.

7. Advances in Prosthetic Joint Technology

In addition to materials that make up the structure of custom prosthetics, advancements in prosthetic joint technology have greatly impacted how prosthetics function. Modern joint materials focus on replicating natural movement, allowing patients to perform daily activities with greater ease and stability. These materials are engineered to handle repetitive motion and weight-bearing, making them highly durable for long-term use.

Materials like titanium and other high-strength alloys are commonly used in prosthetic joints due to their durability and biocompatibility. Medical professionals working with patients requiring joint replacement should understand these materials’ benefits and limitations, as well as how they integrate with other advanced prosthetic technologies.

Contact Grace Prosthetic Fabrication for Custom Prosthetic Fabrication

The field of prosthetics is evolving rapidly, with new materials and technologies driving improvements in functionality, comfort, and patient outcomes. For medical professionals, staying informed about these emerging trends is crucial to provide the best possible care and guidance for patients. From lightweight composites and 3D printing to antimicrobial and smart materials, the options available in custom prosthetics are more advanced and versatile than ever before.

By embracing these trends and understanding the advantages of each material, medical professionals can play a pivotal role in enhancing the lives of those who rely on prosthetics. Grace Prosthetic Fabrication remains at the forefront of these advancements, committed to providing innovative solutions that meet the unique needs of every patient. As the industry continues to evolve, medical professionals who stay engaged with these trends will be best positioned to deliver impactful, informed care.