The field of prosthetics has seen remarkable advancements over the years, with innovations that continue to improve the quality of life for individuals who need limb replacement solutions. One of the most exciting developments in recent times is the use of 3D printing technology to create custom prosthetics. At Grace Prosthetic Fabrication, we have embraced this cutting-edge technology to revolutionize the way prosthetics are made, providing our patients with highly customized, precise, and comfortable prosthetic solutions.

With over 34 years of experience in the industry, Grace Prosthetic Fabrication has always been at the forefront of innovation. Our commitment to using advanced technology, such as 3D printing, allows us to offer personalized prosthetic solutions that enhance both functionality and aesthetics. In this blog post, we’ll explore how Grace Prosthetic Fabrication is utilizing 3D printing technology to create high-quality prosthetics and why this approach is changing the landscape of prosthetic fabrication.

The Benefits of 3D Printed Prosthetics

3D printing technology has opened new doors in prosthetic fabrication by offering a level of customization and precision that was previously unattainable. At Grace Prosthetic Fabrication, we use 3D printing to create prosthetics that are tailored to the unique needs of each patient, ensuring a perfect fit and optimal functionality.

Here are some of the key benefits of 3D printed prosthetics:

1. Precision and Customization

One of the greatest advantages of 3D printing technology is its ability to create highly customized prosthetics. Using advanced 3D scanning and modeling techniques, we can design prosthetics that are precisely tailored to the patient’s anatomy. This level of customization ensures that the prosthetic fits comfortably and functions seamlessly, reducing the risk of discomfort, irritation, or other complications.

Unlike traditional prosthetic fabrication methods, which often involve manual processes that can lead to slight variations in fit and quality, 3D printing allows for unparalleled precision. Each prosthetic is designed and printed based on the exact measurements and specifications of the patient, resulting in a device that fits like a glove.

2. Faster Production Times

In addition to its precision, 3D printing also offers the benefit of faster production times. Traditional prosthetic fabrication can be a time-consuming process, involving multiple steps and adjustments. With 3D printing, we can significantly reduce the time it takes to produce a custom prosthetic, allowing patients to receive their devices more quickly.

This faster production process is especially beneficial for patients who need their prosthetics as soon as possible, such as those recovering from surgery or injury. At Grace Prosthetic Fabrication, our goal is to provide patients with the high-quality prosthetics they need in a timely manner, and 3D printing technology helps us achieve that.

3. Enhanced Durability and Functionality

Another advantage of 3D printed prosthetics is their enhanced durability and functionality. By using advanced materials and printing techniques, we can create prosthetics that are both lightweight and strong, offering the perfect balance of comfort and performance. These materials are designed to withstand the wear and tear of daily use, ensuring that the prosthetic remains durable and reliable over time.

At Grace Prosthetic Fabrication, we also incorporate our innovative Grace plates technology into our 3D printed prosthetics. Grace plates provide additional strength and stability to the prosthetic, allowing for improved weight distribution and better overall performance. This combination of 3D printing and Grace plates technology ensures that our prosthetics offer superior functionality and long-lasting durability.

4. Aesthetic Customization

Beyond functionality, 3D printing also allows for greater aesthetic customization. Prosthetics created using 3D printing technology can be personalized to match the patient’s skin tone, texture, and even design preferences. This level of customization helps patients feel more confident and comfortable with their prosthetics, as the devices are designed to blend seamlessly with their bodies and reflect their personal style.

Whether a patient prefers a prosthetic that closely resembles their natural limb or one with a unique and artistic design, 3D printing makes it possible to achieve these aesthetic goals. At Grace Prosthetic Fabrication, we believe that prosthetics should not only restore mobility but also empower patients by helping them feel confident in their appearance.

The Grace Prosthetic Fabrication Approach to 3D Printed Prosthetics

At Grace Prosthetic Fabrication, we are dedicated to providing our patients with the highest quality prosthetics using the latest technology available. Our approach to 3D printed prosthetics combines advanced technology with our decades of experience in prosthetic fabrication, resulting in devices that are both functional and personalized.

Here’s how our process works:

1. Comprehensive Assessment and Design

The first step in creating a custom 3D printed prosthetic is a comprehensive assessment of the patient’s needs. Our team works closely with physicians, physical therapists, and other healthcare providers to understand the patient’s medical history, lifestyle, and specific requirements. This collaborative approach ensures that the prosthetic we create aligns with the patient’s overall treatment plan.

Using advanced 3D scanning technology, we capture detailed measurements and images of the patient’s residual limb. These scans are then used to create a digital model of the prosthetic, which is customized to ensure a precise fit and optimal performance.

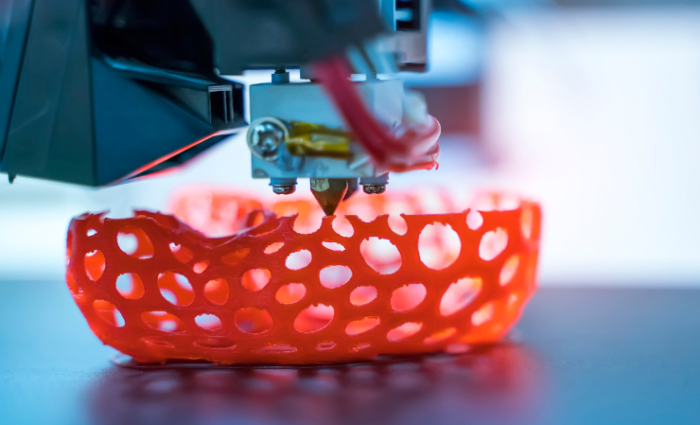

2. Fabrication Using Advanced 3D Printing Technology

Once the design is finalized, the prosthetic is fabricated using our state-of-the-art 3D printing technology. This process allows us to create a prosthetic that is highly accurate and tailored to the patient’s unique anatomy. We also incorporate our Grace plates technology into the design to enhance the strength and stability of the prosthetic.

The use of 3D printing technology allows us to create prosthetics that are lightweight, durable, and comfortable to wear. Each prosthetic is carefully inspected and tested to ensure that it meets our high standards of quality and performance.

3. Fitting and Adjustment

After the prosthetic is printed and fabricated, the patient is fitted with the device to ensure a comfortable and secure fit. During this fitting process, we make any necessary adjustments to ensure that the prosthetic functions properly and meets the patient’s needs. Our team is committed to providing ongoing support and care to ensure that the patient is fully satisfied with their prosthetic.

The Future of Prosthetic Fabrication with 3D Printing

The use of 3D printing technology in prosthetic fabrication represents the future of the industry, offering new possibilities for customization, precision, and performance. At Grace Prosthetic Fabrication, we are proud to be at the forefront of this technological revolution, using 3D printing to create prosthetics that truly make a difference in our patients’ lives.

Our commitment to innovation, quality, and patient care has earned us a reputation as a leader in the field of prosthetics. Whether you are a patient in need of a custom prosthetic or a physician seeking a trusted partner in prosthetic fabrication, Grace Prosthetic Fabrication is here to help.

Contact Grace Prosthetic Fabrication to Schedule a Consultation

With 34 years of experience and a dedication to embracing the latest advancements in technology, Grace Prosthetic Fabrication is your trusted partner for high-quality, custom prosthetics. Our use of 3D printing technology, combined with our innovative Grace plates and collaborative approach with physicians, ensures that every prosthetic we create is tailored to the unique needs of each patient.